Lateral Lining – Documenting A Quality Installatio

By NASSCO Member Tony Araujo, VP Business Development. Paragon Systems Testing

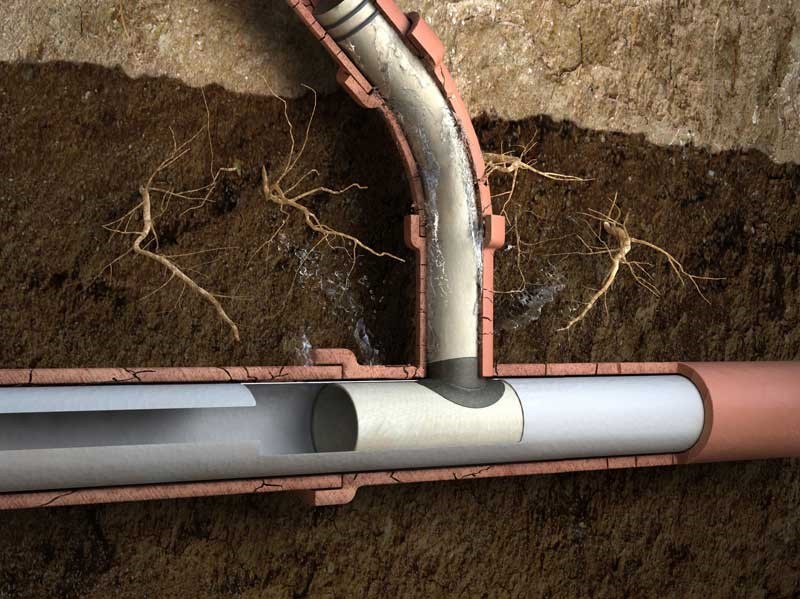

With CIPP lining of mainline sewers becoming more and more accepted by system owners and utilities, greater attention is being paid to the opportunities to reduce infiltration and inflow (I&I) by utilizing CIPP lining for laterals. CIPP manufacturers have developed a wide variety of systems for different lateral lining applications. Just like their larger diameter pipe cousins, lateral lining resins can be either ambient, heat or UV cured and they can be non-reinforced felt-based or fiber reinforced construction. To achieve the life extension objective that owners and utilities are looking for from CIPP lining, it’s just as critical to ensure that the ASTM F1216 physical properties (flexural modulus, flexural strength and wall thickness) of the installed liner comply with the design objective for the installation. Measuring these properties from an installation requires that a physical sample of the liner material used in the installation be cured in the same manner as the installation. This cured sample is then tested in a laboratory to confirm the physical properties.

Because of this necessity to obtain physical samples, until recently measuring these properties from lateral installations has been considered challenging and costly especially when compared to sampling and testing mainline sewers. But, given the accumulating knowledge of natural variation in CIPP physical properties in mainline sewers due to the field manufactured nature of CIPP, owners, utilities and contractors are starting to look for ways to efficiently sample and test their lateral installations for the same reason they do for mainline sewer rehabilitation – to ensure they achieve life extension for these critical lateral assets.

The practice of sampling and testing mainline sewer CIPP installations is well established. The goal for each of the methods is to obtain material which is as representative of the installed CIPP as possible. Three basic types of samples are in current use: restrained, plate and direct cut. Restrained samples are formed by passing the impregnated tube through a cylindrical form, typically a short section of PVC pipe of the same diameter as the installation, which is then pressurized and cured along with the installation. Plate samples consist of a section of impregnated tube which is sandwiched between two metal plates. This sandwich is then placed inside of the liner and cured along with the installation. Finally, direct-cut samples are actually cut from the wall of the sewer after installation. This sampling method leaves a hole in the CIPP that must then be repaired either with a spot repair or some other owner approved method. Each method is a compromise but all have been used successfully in thousands of installations to confirm that a main line installation is design compliant.

These methods were all designed around pipes which are larger diameter than your typical lateral but, depending on the CIPP system being used, they can be adapted for sampling of lateral CIPP installations. For example, plate samples can be used for ambient cured laterals which are launched from the main. A segment cut from the impregnated tube prior to installation and sandwiched between plates can be cured at the bottom of a manhole where the environment approximates that of the lateral being lined. This is an economical and efficient lateral sampling method presently being employed by multiple utilities. Restrained samples for heat or UV cured laterals can be obtained in those cases where it is necessary to access the lateral from a pit within the building where the lateral terminates. Just as is currently done for main line samples, the impregnated tube is passed through a PVC pipe of the same diameter as the lateral and is then pressurized and cured along with the installation.

Because of the space constraints inside of manholes, main line UV liners are frequently sampled using a surrogate sample which is made above ground with an additional segment of impregnated tube contained with a segment of pipe. While this is obviously a more involved and expensive sampling method, it can be considered for laterals especially where the lateral being lined is underneath critical infrastructure where the consequences of failure would be more significant. Even a form of direct cut samples is possible to employ in those cases where the pipe being lined is fully accessible as is the case inside of buildings. In these cases, a full diameter segment of lined pipe can be removed and sent to the laboratory for testing.

Of course, sampling and physical properties testing is only one part of a comprehensive QA program. Resin components are typically mixed on-site and then manually impregnated into the carrier tube by the installation crew prior to installation. A good QA program should ensure that actual installation parameters are documents for each installation. This could include resin lot numbers, volumes used, roller separation, resin mix time, installation pressure, cure temperature log and outside temperature.

TECH TIPS IS A BI-MONTHLY ARTICLE ON TRENDS, BEST PRACTICES AND INDUSTRY ADVICE FROM NASSCO’S TRENCHLESS TECHNOLOGY MEMBERSHIP PROFESSIONALS