UNDERSTANDING STYRENE AND CIPP

By NASSCO Technical Advisory Council Chair Christopher Garrett, P.E., Brown and Caldwell

The topic of styrene safety has garnered a lot of attention in recent years. For more than a decade the effects of styrene cure water and condensate have been documented on receiving waters. Since 2017 academic research and customer concerns about CIPP acute and chronic health concerns has brought this issue to the forefront for suppliers, contractors, engineers, and owners. As the CIPP industry looks forward to the next 50 years of providing effective rehabilitation of our aging infrastructure, a better understanding of styrene emissions is an idea whose time has come.

NASSCO is committed providing sensible best practices that promote worker safety while funding research to evaluate the challenge and establish a scientific basis for future recommendations. Styrene is the ideal monomer used for cross-linking polyester and vinyl ester resins. Due to its history of success, styrene is preferred over alternative monomers for CIPP. With a low threshold for human detection, styrene odor from CIPP installations has documented complaints from utility customers who are concerned about protections and exposure concerns with CIPP.

To date, styrene-based resins are not used in CIPP rehabilitation of drinking water assets, and potential odors from sanitary sewer installations can be significantly reduced by filling household plumbing traps with water. Also, styrene emissions from CIPP are not regulated. Industry advocates and regulatory agencies have published widely varying exposure thresholds, including the United States Environmental Protection Agency (EPA), the National Institute for Occupational Safety and Health (NIOSH), the Occupational Safety and Health Administration (OSHA), and the American Conference of Governmental Industrial Hygienists (ACGIH). Amongst these varying exposure limit thresholds, limiting human exposure to less than 20 parts per million (ppm) is a conservative basis that could be a standard for establishing work site best practices.

Styrene Facts Regarding CIPP

• Styrene is a monomer that is an important component of the CIPP thermoset resins for the past 50 years

• Polyester and Vinyl Ester resins contain approximately 23% to 40% styrene • Styrene is generally noticeable at levels less than 1 ppm

• There is no regulatory standard for styrene emission. Different thresholds for exposures are published – EPA has a guideline for human emission exposure at 20 ppm for any duration

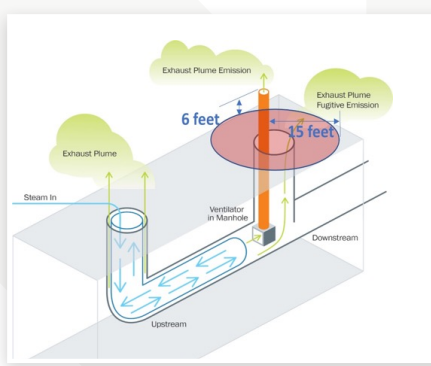

• NASSCO’s “Guidelines for the Safe Use and Handling of Styrene-Based Resins in CIPP” recommends a 15-foot perimeter around emissions and exhaust stacks a minimum of 6 feet above ground as mitigative measures to ensure low styrene exposure.

NASSCO has been providing industry leadership with the development and adoption of recommended industry practices for the handling of styrenated resins for CIPP. In 2009, NASSCO published the inaugural “Guidelines for the Safe Use and Handling of Styrene-Based Resins in CIPP.”

This guideline was updated in later versions, culminating in the 2020 standard that incorporated findings from Trenchless Technology Center’s (TTC) “CIPP Emissions Phase 2: Evaluation of Air Emissions from Polyester Resin CIPP with Steam Cure.

For worker safety, the guidelines include the following:

• Establish a work zone perimeter of a 15-foot cleared radius around emission stacks, with stack discharges being a minimum of six (6) feet above ground surface. Workers should avoid entering the cleared perimeter for prolonged exposures.

• Equip workers with appropriate protections when entering the cleared perimeter and other areas with possible styrene exposure.

• Consider localized job site air monitoring to confirm that safety measures are working as intended, with provisions for additional protective measures as needed.

TECH TIPS IS A BI-MONthly article on trends, best practices and industry advice from NASSCO’s Trenchless Technology membership PROFESSIONALS

Follow us on social media or visit NASSCO.org