PACP Condition Grading System

By Tanya Stephens, A.Sc.T., NASSCO-Certified Trainer

Each of NASSCO’S Pipeline Assessment Certification Program (PACP) inspection reports offer eight or nine different condition grades:

- Structural Quick Rating

- Operational and Maintenance (O&M) Quick Rating

- Overall Quick Rating

- Structural Pipe Rating

- O&M Pipe Rating

- Overall Pipe Rating

- Structural Pipe Rating Index

- O&M Pipe Rating Index

- Overall Pipe Rating Index

How each of these condition ratings are calculated is outlined within the PACP Manual Appendix C, but what do they mean and how can they be interpreted?

It is important to acknowledge that the PACP Condition Ratings are a product of Condition Grades (1 through 5) and the number of occurrences that each Condition Grade is observed. Consider two separate pipes: one with one hole, and the other with five holes. Both pipes have the same “hole structural grade 4 severity” however, one pipe is in much worse condition than the other because the number of occurrences of the holes is greater. An overall condition must consider the severity of the defects observed as well as the extent of defects observed.

The condition grading system only refers to the condition of the pipe length surveyed. It does not reflect asset management principles. Some might consider that if a hole occurs on a short section of pipe versus a long section of pipe, the short section of pipe should be considered in worse condition. This is not the case. A hole is a hole, the same defect, the same severity, regardless of pipe size, length, material, etc. However, a hole in a sanitary sewer versus a hole in a storm sewer might be considered a higher risk once applying asset management principles to condition data. Applying asset management principles to PACP inspection data allows asset inventory reporting, condition reporting, tracking of deterioration over time, map results, setting priorities and consequence of failure, assigning rehabilitation and maintenance needs, and risk assessment.

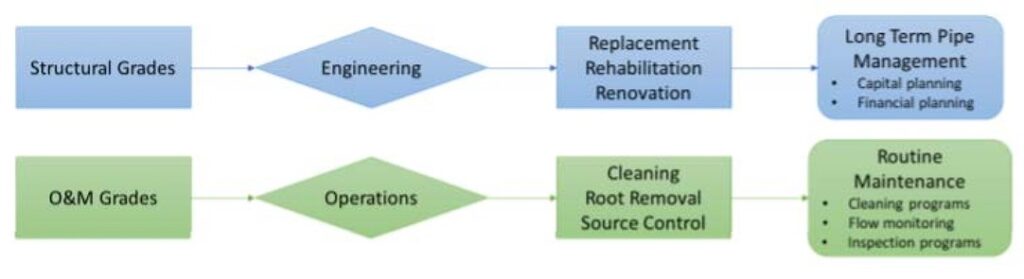

PACP condition grades are assigned as either structural or O&M, and condition ratings are reported separately as structural, O&M, and overall. This is an important distinction as it allows owners to quickly determine the department that should be attending to the pipe. Structural defects are often associated with performance models, life cycle and financial reporting including capital planning. High structural grades drive more urgent/higher priority for replacement or rehabilitation.

Pipe sections resulting in high structural grades typically require engineering assessment. O&M defects trigger routine maintenance and operational activities such as pipe cleaning, root removal and infiltration control. Pipes displaying high O&M ratings and low structural ratings may trigger short term intervention strategies from Operations. A pipe section displaying both structural and operational failures would result in an engineering assessment as structural failures take precedence over conveyance issues and O&M defects are removed during repair or replacement activities. The Quick Rating reports the worst-case scenario in the pipe. It is often overlooked because it is an alphanumeric 4-digit rating system. PACP Quick Rating reports the peak severity grade observed in the pipe in addition to the number of occurrences of that grade.

The PACP Quick Rating, therefore, suggests a condition-based priority to the pipe section as well as a high-level determination of the extent of the repair required; four or more occurrences of structural defects may suggest full-length pipe attention while one or two occurrences may suggest a localized replacement or repair. Similarly, 45 occurrences of 10% deposits may require heavier cleaning or several passes of a jetter. When displaying condition data within a GIS, it is often best to thematically map condition using the first number of the Quick Rating. This reports the worst-case scenario to asset owners.

The pipe rating is an infinite number, and one might incorrectly assume that the higher the number, the worse the condition of the pipe. For example, 9 occurrences of a grade 5 defect would result in a Pipe Rating 45. Similarly, 45 occurrences of a grade 1 defect would also result in a Pipe Rating 45. Finally, the Pipe Rating Index reports the average severity grade observed in the pipe to one or two decimal places. Since it is reported on a scale of 1-5, asset owners prefer the Pipe Rating Index for reporting and mapping. Asset owners should beware of prioritizing works based on averages; consider a Pipe Rating Index 3, it takes only 6 grade 1 defects to “hide” the fact that there are 6 grade 5 defects within the pipe section.

All stakeholders should have a solid understanding of PACP data, how it is collected and how condition ratings are reported. Remember, condition ratings are assigned to each survey; should a survey be abandoned, and a reversal is performed, two surveys’ combined condition ratings should make up the overall condition of the pipe section.

TECH TIPS IS A BI-MONTHLY ARTICLE ON TRENDS, BEST PRACTICES AND INDUSTRY ADVICE FROM NASSCO’S TRENCHLESS TECHNOLOGY MEMBERSHIP PROFESSIONALS

Follow us on social media or visit NASSCO.org